Airbus Engine Factory

Hamburg, Germany

As a model for sustainable airplane engine factories of the future, this project forms part of a broad strategy to rapidly decarbonize the aviation industry. The design expands beyond traditional architectural boundaries, advancing both sustainable construction and manufacturing practices for the Hamburg campus. Addressing the building’s expansive impact required both large and small strategies for embodied and operational carbon. Proven low-carbon materials like mass timber were paired with next-generation innovations such as CO₂-sequestering concrete and bio-based cement.

Work completed while at The Living

Size: 100,000 ft²

Client: Airbus

Sustainability: DGNB Gold

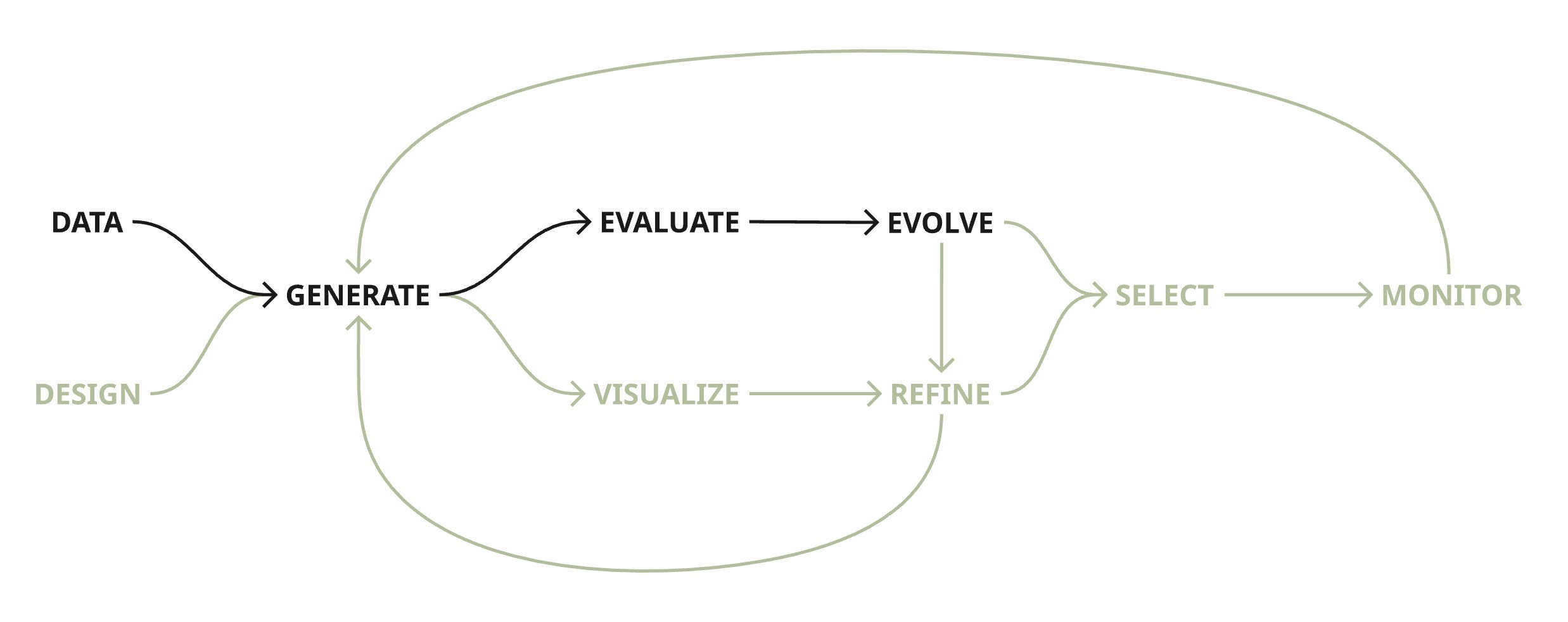

Scope: Architecture, Generative Design

Team: David Benjamin, Lindsey Wikstrom, John Locke, Ray Wang, Lorenzo Villaggi, Damon Lau